Product Description

ANON provides 50-60TPD fully automatic rice mill production line. From paddy cleaning to rice packing, the operation is automatically controlled. Good quality, reasonable price, and professional technical support should be provided. It can produce rice 50-60 tons per day.

The Complete Rice Mill Production Line is a kind of comprehensive equipment for rice processing. Rice goes into machine through vibrating screen and magnet unit, and then forward under rubber-roller for hulling. Winnowing and air blowing to husk. The machine may complete all the processing works from cleaning grain, rice husking in hulling to rice husking in succession. As to husk, chaff, blighted grain as well ad polished rice, they are all pushed out of machine separately. This machine is comprehensive expression for all the good qualities of varied kinds of rice-processing machines. For instance, it is arranged with a comprehensive view of situation and is designed rationally.

SpecificationWorking flow

| Pre Cleaning | Removing all impurities and unfilled grains from raw paddy |

| De-stoning | Separating small stones from paddy |

| Husking | Removing husk from paddy |

| Husk Aspiration | Separating the husk from brown rice/ unhusked paddy |

| Paddy Separation | Paddy Separation |

| Whitening | Removing all or part of the bran layer and germ from brown rice |

| Polishing | Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of milled kernel |

| Color Sorting (Optional) | Removing foreign materials such as colored, broken, immature and insected grains from milled rice |

| Length Grading | Separating small and large brokens from head rice |

| Blending | Mixing head rice with predetermined amount of brokens, as required by the customer |

| Weighing and Bagging | Preparing the milled rice for transport to the customer |

More Options

| Parboiling (Optional) | Improving the nutritional quality and milling recovery percent during husking and polishing / whitening operation |

| Paddy Dryer | Drying raw paddy with high moisture |

| Thickness Grader | Removing broken and immature grains from brown rice before whitening |

| Flow Scale | Flow controlling and incontinuous accumulating measure of white rice |

| Hammer Mill | Milling chaff into grainy materials |

| Rice Hull Separator | Separating paddy and broken brown rice from husk |

| Bran Separator | Separating broken rice from rice bran |

Detailed Pictures

Company Information

Customers' Visit

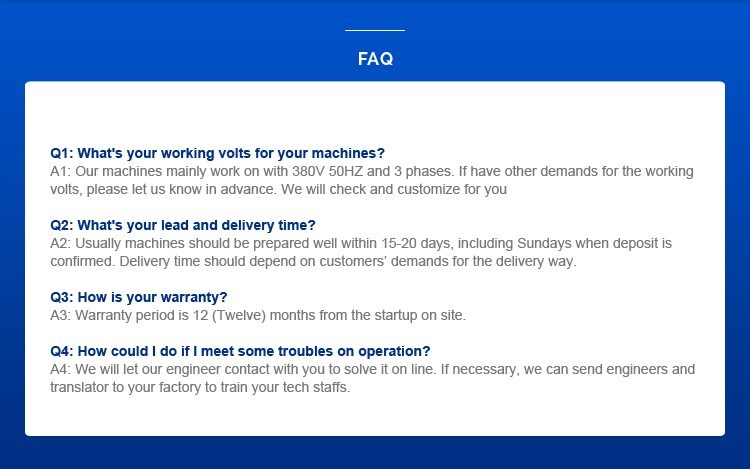

FAQ

How to Order

Contact Your Sales