From factory establishment, we have been insisting manufacturing full set of beneficiation equipments. With over 23 years' experience, we have a brance in Tibet, by now we have mature technical, rich experience, perfect service, reliable qualtiy, best after sale service and plenty of custome site for your reference.

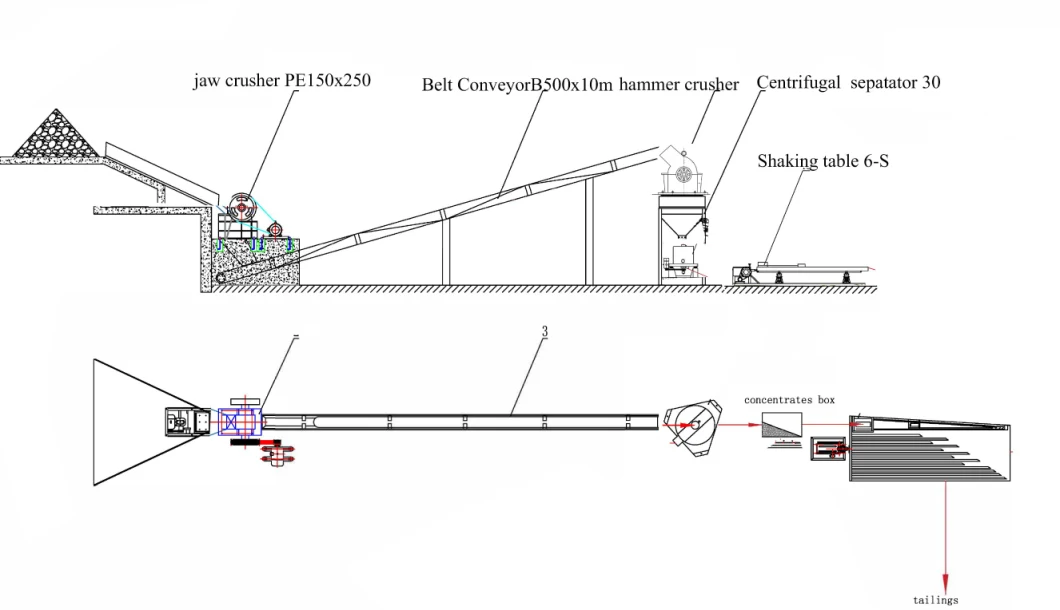

The gravity separator machine is suitable for concentrating of alluvial gold.The specific process is different according to ore, site and customers' requirements.

The gravity separator machine is suitable for concentrating of alluvial gold.The specific process is different according to ore, site and customers' requirements.

Capacity(t/d) : 30 T/D - 3000 T/D

The Rock hammer crusher (hammer mill) crushes by the collisions between high-speed hammer and materials, and the hammer crusher (hammer mill) features are in its simple structure, high reduction ration, high efficiency, etc. The PC hammer crusher (hammer mill) were developed for both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum & chemical industries.

Main Feather:

1. Higher capacity,big crushing ratio.

2.Low power consumption,uniform output size.

3.compact and easy to be moved.

4.easy for maintenance.

5.High fineness of discharging size.

6.Low running cost.

Gold centrifugal concentrator can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation. It is also used to recover gold from the old tailings.

Features :

1. High concentrating ratio and high recovery;

2. Total process automation, steady recovery performance;

4. Environmentally friendly ( no chemical additives or reagents);

5. Low water and electricity requirements;

6. Low production costs, durable wear parts, minimal maintenances requirements;

7. Compact design requiring less space, easy merged into the existing mining processing;

8. Quick payback on investment, typically less than a half-year.

It is one of the main equipment of gravity concentration. This table mainly by the head of a bed, motor, adjustable slope, bed, ore groove, groove, reflex and lubrication systems of eight parts. According to the mine in different position, shaking table can be divided into right and left shaking table two forms. The right table feed position for shaking organizations on the right, the left table to mine position on the left.

Advantages

1. Get concentrate and gangue at one time

2. Fine water-resistance, chemical resistance, corrosion resistance, abrasion resistance, etc;

3. We can simplify the repair and painting process, which directly reduces the maintenance cost, greatly increases recovery

rate, and prolongs the life of ore concentration tables.

4. High enrichment ratio, good selection effect, easy operation

5. Low energy consumption, competitive price

| Performance Parameters of Hammer Crusher | ||||||

| Model | Rotor speed (r/min) | Feeding size (mm) | Discharging size(mm) | Capacity (t/h) | Power (Kw) | Weight (t) |

| PC400×300 | 1200 | ≤80 | ≤10 | 5-8 | 11 | 0.7 |

| PC600×400 | 1000 | ≤110 | ≤15 | 10-15 | 18.5 | 1.5 |

| PC800×600 | 980 | ≤120 | ≤15 | 20-25 | 55 | 3.7 |

| PC1000×800 | 980 | ≤200 | ≤45 | 34-54 | 110 | 6.9 |

| PC1000×1000 | 1000 | ≤200 | ≤15 | 40-60 | 132 | 8.5 |

| PC1200×1000 | 745 | ≤200 | ≤25 | 75-150 | 160 | 12.5 |

| PC1200×1200 | 745 | ≤200 | ≤20 | 80-160 | 185 | 14.3 |

| PC1400×1400 | 750 | ≤250 | ≤20 | 120-170 | 280 | 17.2 |

| PC1600×1600 | 500 | ≤350 | ≤20 | 220-290 | 500 | 32.4 |

| PCK600×600 | 1250 | ≤80/≤40 | ≤3 | 75-15/15-30 | 55 | 2.4 |

| PCK800×800 | 1250 | ≤80/≤40 | ≤3 | 25-30/50-70 | 110 | 3.6 |

| PCH600×400 | 970 | ≤200 | ≤30 | 22-33 | 15 | 1.7 |

| PCH600×600 | 980 | ≤200 | ≤30 | 30-60 | 30 | 2.4 |

| PCH800×800 | 825 | ≤300 | ≤30 | 75-105 | 45 | 4.8 |

| PCH1000×1000 | 740 | ≤300 | ≤30 | 90-150 | 90 | 7.5 |

| Centrifugal gold separator | |||||||||

Model | Capacity (t/h) | Power (kw) | Feed size (mm) | Slurry density (%) | Backlash water quantity (kg/time) | Concentrates capacity (kg/time) | Cone rotation speed (r/min) | Water pressure (mpa) | Weight (t) |

STL-30 | 3-5 | 3 | 0-4 | 0-50 | 6-8 | 10-20 | 600 | 0.05 | 0.5 |

STL-60 | 15-30 | 7.5 | 0-5 | 0-50 | 15-30 | 30-40 | 460 | 0.16 | 1.3 |

STL-80 | 40-60 | 11 | 0-5 | 0-50 | 25-35 | 60-70 | 400 | 0.18 | 1.8 |

STL-100 | 80-100 | 18.5 | 0-6 | 0-50 | 50-70 | 70-80 | 360 | 0.2 | 2.8 |

| shaking table | |||||||

| Model | 6-s 4500 | 6-s 3000 | 6-s 2100 | 6-s 1100 | |||

| Deck type | coase deck | fine deck | slurry deck | three type of decks optional | |||

| Beneficiation area(m2) | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

Deck size (mm) | Length | 4500 | 4500 | 4500 | 3000 | 2100 | 1100 |

| Transmission width | 1850 | 1850 | 1850 | 1320 | 1050 | 500 | |

| Concentrate width | 1550 | 1550 | 1550 | 1100 | 850 | 430 | |

| Stroke(mm) | 16-22 | 11-16 | 11-16 | 6-30 | 12-28 | 9-17 | |

| Frequency of stroke (r/min) | 220 | 250 | 250 | 210-320 | 250-450 | 280-460 | |

| Max feeding size(mm) | 2 | 0.5 | 0.5 | sand-2 slurry-0.1 | sand-2 slurry-0.074 | sand-2 slurry-0.074 | |

| Water consumption(t/h) | 0.7-1 | 0.4-0.7 | 0.4-0.7 | 0.3-1.5 | 0.2-1 | 0.1-0.5 | |

| Slope(°) | 0-5 | 0-10 | 0-8 | 0-8 | |||

| Motor power(kW) | 1.1 | 0.5 | |||||

Henan Xingyang Mining Machinery Factory was established in 1996 . Is engaged in mineral processing equipment, product development, engineering and production and sales of new technology enterprises. Enterprises adhere to the implementation of entrepreneurial talent , science and technology, quality in setting development strategy, according to domestic and international market situation, based on the original mineral processing equipment ( crusher, ball mill , flotation machine, magnetic separator , dryer , etc. ) , actively the introduction of advanced high-tech , research and development of a series of energy-saving ball mill , MQG ball mill, flotation machine series , stirred tank , pellet equipment ( Run mill , rotary kiln, balling plate , cooler, coal mill ) and magnesium production line ( zinc oxide production line, limestone lines ) and other products with the leading domestic level , some products have reached the international advanced level.

Henan Xingyang Mining Machinery Factory was established in 1996 . Is engaged in mineral processing equipment, product development, engineering and production and sales of new technology enterprises. Enterprises adhere to the implementation of entrepreneurial talent , science and technology, quality in setting development strategy, according to domestic and international market situation, based on the original mineral processing equipment ( crusher, ball mill , flotation machine, magnetic separator , dryer , etc. ) , actively the introduction of advanced high-tech , research and development of a series of energy-saving ball mill , MQG ball mill, flotation machine series , stirred tank , pellet equipment ( Run mill , rotary kiln, balling plate , cooler, coal mill ) and magnesium production line ( zinc oxide production line, limestone lines ) and other products with the leading domestic level , some products have reached the international advanced level.

-Pre-sale services

Based on the clients' request and budget, we will offer equipment pictures, working site videos, plant processing diagram, assemble drawings, foundation drawings, and plant layout. Clients are welcome to visit our factory, also our equipment working site from former clients. We will arrange cars, hotels and translators for the visiting customers.

-Sale services

Our experienced technicians is available on the phone also the internet, clients can get instance guidance by telephone, email, online service anytime, anywhere. As clients' request, we will send technician to the mine site to guide the installation, trial run test, and training operators until the plant works normally.

-after-sale service.

Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.