Product description

The spiral chute is a combination of the features of a spiral concentrator, a spiral chute, a shaker and a centrifugal concentrator. It is the best equipment for mining and beneficiation, especially for sand mining on the seashore, riverside, sand beach and stream ideal.

This equipment is suitable for the separation of iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphonite, tungsten ore, tin ore, strontium with a particle size of 0.3--0.02 mm. Mines, antimony ore and other non-ferrous metals, rare metals and non-metallic mineral bodies with different specific gravity.

Spiral chute advantages

1: The structure of the spiral chute is reasonable, the installation is simple, and the floor space is small.

2: The spiral chute is easy to operate, the ore dressing is stable, the mine is clear, the treatment volume is large, the efficiency is high, the enrichment ratio is high, the recovery rate is high, and the operation is reliable.

3: The spiral chute has the advantages of light weight, moisture resistance, rust prevention, corrosion resistance, strong adaptability to the ore content, concentration, grain size and grade fluctuation, no noise, etc.

4: The spiral chute has small footprint, low water consumption, simple structure, no power, large processing capacity, easy installation, convenient operation, small investment and quick effect.

Spiral chute operating principles

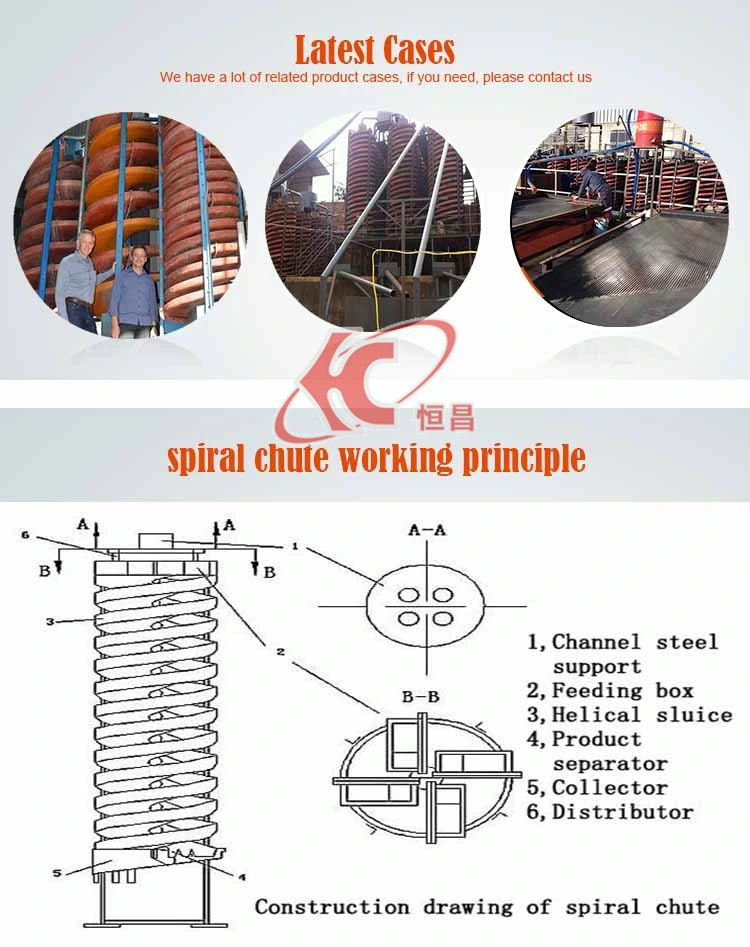

The structure of spiral chute :

The spiral chute separator has a feeding uniformizer, a cross (tripod), a feeding trough, a spiral trough, a troughing trough, a collecting bucket, and a trough strut.

The working principle of mining spiral chute:

Raise the spiral chute, calibrate the vertical line, fix it in the appropriate position with iron frame or wood, send the ore to the top of the spiral feed by the sand pump, add the supplementary water, adjust the concentration of the ore paddle, the natural paddle Swirl from high to low, generating an inertial centrifugal force in the rotating bevel flow rate. Separating the ore from the sand by the gravity and centrifugal force of the swirling flow, the difference in the specific gravity, grain size and shape of the ore. The inflow of the concentrate bucket is taken out by the pipeline, and the tailings flow into the tailing sand bucket to connect to the sand pool, and then drained by the sand pump to complete the whole process of the beneficiation.

Technical parameter

Model | LL-2000 | LL-1500 | LL-1200 | LL-900 | LL-600 |

Diameter(mm) | 2000 | 1500 | 1200 | 900 | 600 |

Pitch(mm) | 1200/1500 | 540/720 | 540/720/900 | 405/540/675 | 270/360/450 |

Pitch Ratio | 0.6/0.75 | 0.45/0.6 /0.75 | 0.45/0.6 /0.75 | 0.45/0.6 /0.75 | 0.45/0.6 /0.75 |

Slope(°) | 9 | 9 | 9 | 9 | 9 |

Head | 4 | 4 | 4 | 4 | 3 |

Input Size(mm) | 0.04-2 | 0.02-2 | 0.03-0.3 | 0.03-0.3 | 0.02-0.2 |

Input Thickness(%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 |

Capacity(t/h) | 12-30 | 6-12 | 4-6 | 2-3 | 0.8-12 |

Dimension (mm) | 2100×2100 ×5600 | 1580×1580 ×5230 | 1360×1360 ×5230 | 1100×1100 ×4000 | 700×700 ×2600 |

Weight(kg) | 2000 | 1100 | 600 | 400 | 150 |

Our service

1) Installation and guidance

When the machine arrives at your company, we will dispatch our technicians to your company to guide the installation and commissioning at site. User should pay for the following fees air tickets, boarding and lodging and traffic in client's factory.

(2)Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3)Warranty:

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: 30% advanced payment by T/T, balance paid before shipment.

Why Choose Us?

1.We are true Manufacturer.

2.Alibaba Assessed Gold Supplier.

3.Inspected by the Inspection Institution of ISO CE Certification.

4.100% QC inspection Before Shipmeng.

5.Best Quality & Best Service with Competitive price

Contact us

If you want to know more details, please contact me!!

Website:http://hcmining.en.made-in-china.com

Tel: +86-15516999978