1.wet type magnetic separator introduction:

Wet type magnetic separator machine Instruction: This series of wet magnetic separator is used in wet magnetic separation of materials with granularity below 3mm like magnetite, pyrrhotine, bake ore and washingtonite. It is also used for deironing materials like non-metal ores, coal and building materials.

Wet type magnetic separator machine Average magnetic induction of barrel surface is 100-600mT. According to customers' demands, it can provide magnetic separation with different magnetic induction like forward flow, semi counter flow and counter flow. The products have features, such as simple structure, high yield, convenient operation and easy maintenance.

We have semi-counter current trough, counter current, fair current troughs.

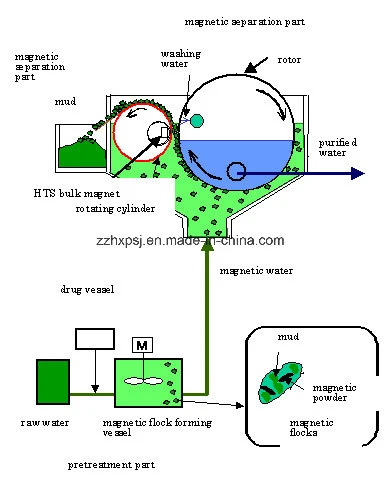

2.Working principle of the wet type magnetic separator:

The pulp flows into cell body from the pulp box, and under the water flow of the feeding spray pipe, the mineral grain will go into the feeding area of the cell body in the loose condition. In the magnetic field, the magnetic ore particles will have magnetic gathering and form magnet group or magnet chain which is influenced by the magnetic force inside the pulp and moves to the magnetic pole and finally is absorbed onto the cylinder.

3.wet type magnetic separator technical specifications :

| Model | Magnetic density(oe) | Capacity(t/h) | Power(kw) | Weight(kg) |

| CTB600X900 | 1450 | 8-15 | 1.1 | 910 |

| CTB600X1800 | 1500 | 15-25 | 2.2 | 1340 |

| CTB750X1800 | 1550 | 30-45 | 3 | 2050 |

| CTB900X1800 | 1650 | 35-60 | 4 | 3000 |

| CTB1050X2400 | 1650 | 60-95 | 5.5 | 5020 |

| CTB1200X3000 | 1650 | 80-150 | 7.5 | 7800 |

| CTB1500X3000 | 1650 | 120-200 | 11 | 9600 |

4.wet type magnetic separator features:

(1) Wet drum magnets have high magnetic recovery and discharge.

(2) The feed slurries recover the magnetic.

(3) It is available in single or multiple drum applications.

(4) Recover magnetic solids in as clean as a magnetic concentrate.

(5) Permanent magnet assembly eliminates coil burn-outs

(6) The magnet/pole elements are bolted to a mild steel shaft.

(7) The drum is made from thick stainless steel for long service life.

(8) Wet drum separators are available in different configuration like single drum, double drum and multiple drum. In double drum two separators are arranged back to back with a common feed back.

About factory :

Zhengzhou Hengxing Heavy Equipment Co.,Ltd is a joint stock corporation integrating with research, manufacture and sale which targeted at the large and medium sized series of heavy equipments. Our main products are stone crushing machines, sand making machine ,ball mill machine ,mineral ore dressing machines,rotary dryer,rotary kiln, AAC block making machine, briquetting machine,which were widely used in mineral processing and construction industry.

Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

For more magnetic separator information ,please contact :

Sara

Mobile phone: 0086137 8347 1727

Company Website: zzhxpsj.en.made-in-china.com