Applications and Features:

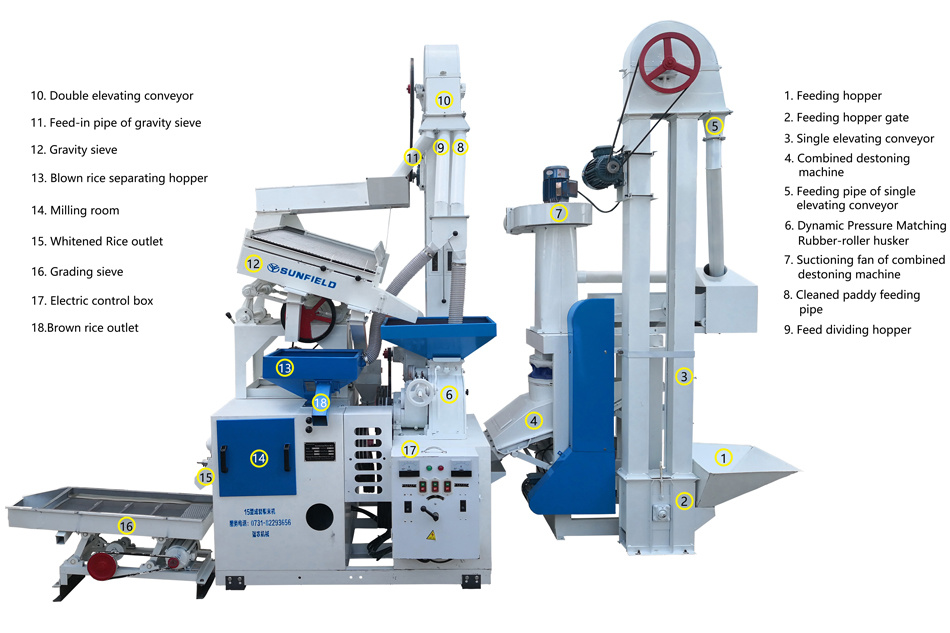

6LN-15/15SD complete set of combined rice milling equipment is composed of TQLQ45 combined trash and stone removal machine, 6-inch rubber roller grain huller, grain separator, emery roller rice mill, broken rice separator, lifting unit, etc. It has excellent brown rice separation and whitening effect, easy operation, convenient maintenance, high work efficiency, and low residue; this machine has brown rice straight out function, which provides users with flexible function matching. At the same time, this machine can be matched with subsequent White rice multi-stage separation sieve, polishing machine, color sorter, etc. get more functions and better rice polishing effect.

Main Technical Performance Indicators:| Model | 6LN-15/15SD |

| Rated output (kg/h) | 700-900 |

| Matching power (kW) | 19.87-24.62 |

| Rice output rate | 68-72% |

| Small broken rice rate | 2% |

| Machine weight (kg) | 1250 |

| Working size (length×width×height) (mm) | 3400×1500×2900 |

1, Unique combination cleaning and stone removal machine

Separate design for cleaning and removing stones, the use effect is much better than the traditional integrated design;

The cleaning part adopts a multi-layer reciprocating shaker mechanism, which has high cleaning efficiency and clean up;

The stone removing part adopts a large air volume suction design, with large air volume and excellent stone removing effect;

High-strength vibration-absorbing bearing configuration, the machine body moves smoothly, is firm and reliable, has low vibration, low noise and low dust.

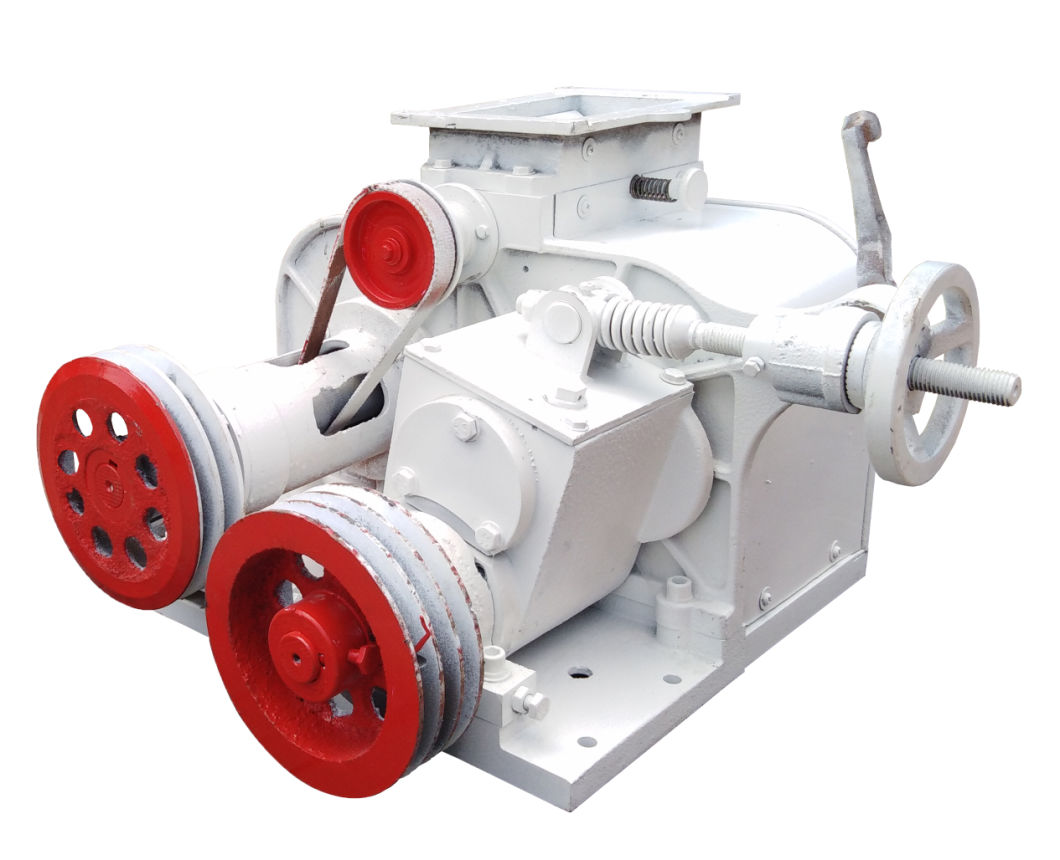

2, Efficient shell-breaking, low-noise hulling machine

The dual-support mobile gearbox hulling machine integrates the direction-changing gearbox and the mobile tight roller device into one, avoiding the problem of coordination and cooperation of swing gears;

The one-time shelling rate exceeds 90%;

The rubber roller has a longer life, convenient operation and adjustment, high transmission efficiency, low noise and high stability.

3, Innovative strong drawing wind sand roller

crushing mill

The emery roller rice mill adopts a large-diameter hollow main shaft and an innovative "sand roll whitening" design;

Strong wind blower, rice temperature is low, rice output is cleaner, and effectively improve the gloss of rice and reduce the rate of broken rice;

The operation height is reduced, the operation is more convenient, and the daily maintenance is convenient.

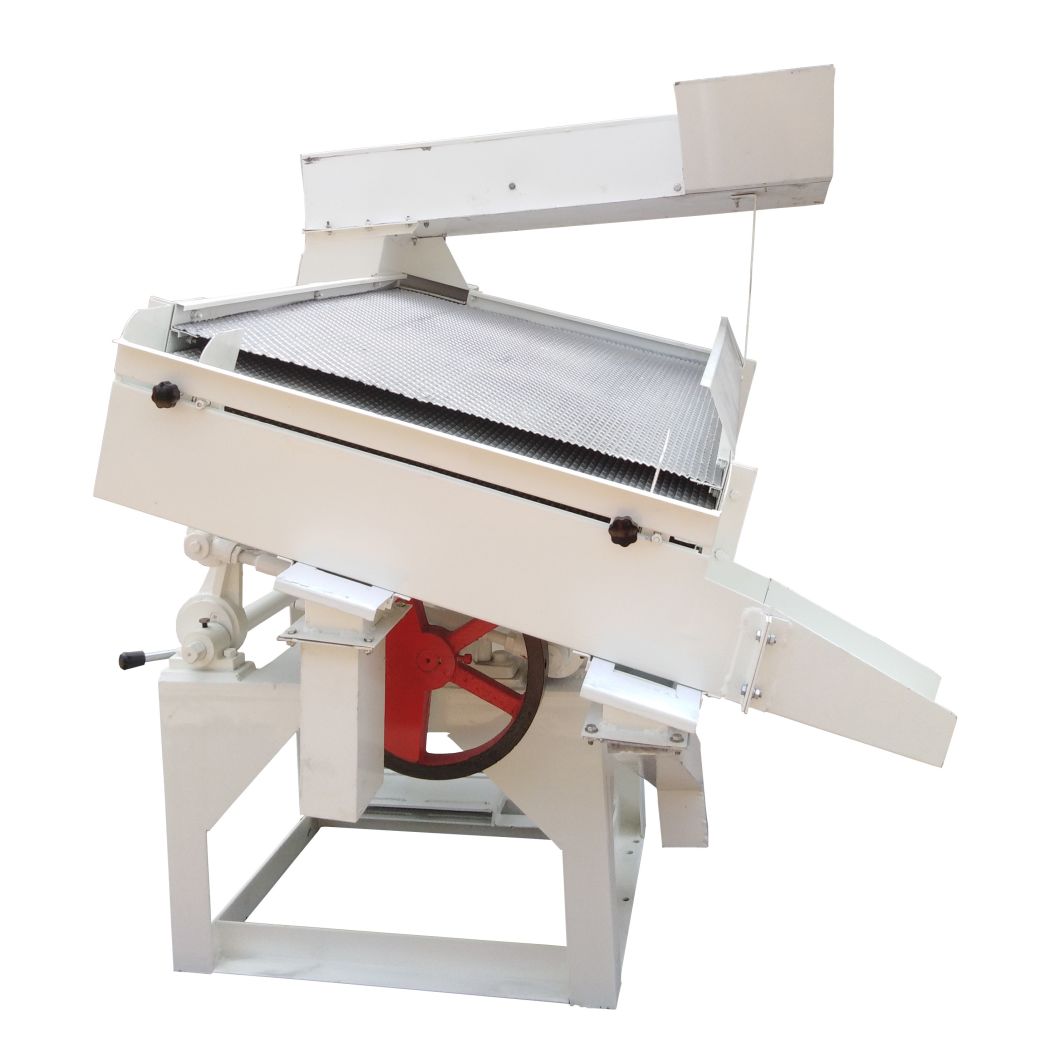

4, Stable Gravity Rough Separation Screen

Large screen surface design, fast separation speed, uniform distribution;

The horizontal and vertical angles of the screen surface can be adjusted to adapt to all varieties of rice, and the screening effect is good;

Less hulling, effectively reducing broken rice. rate.

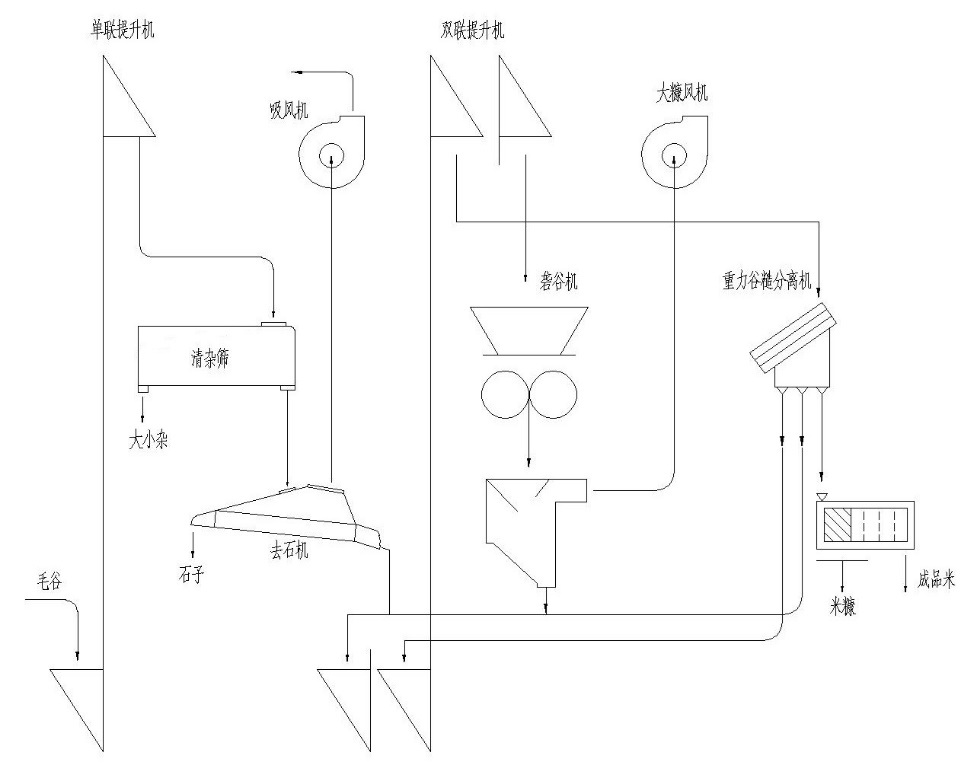

Process flow chart:

Factory Pictures:

Pre-Sales Service:

1. Inquiry and consulting support

2. Sample testing support

3. View our Factory

After-Sales Service:

1.pay the double air tickets, accommodation and food. Our technicists can help you in local place

2.According to the requirement of the buyer, our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's workers on operation, maintenance, etc.

3.Supply the solutions for different farming environment.

4. For the damage caused by the users, our company provides the parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to clients.

Package&Shipping:

Products will be finished in 15-20 working days after payment. It depends on your order quantity. And the shipping time to the port is about 1-2 days